PRODUCTS

PRODOTTI

-

SPECIALIST BEDS

-

WARD FURNITURE

-

CONSULTING ROOMS & CLINICS

CONSULTING ROOMS & CLINICS

-

TECHNICAL WALL SOLUTIONS

TECHNICAL WALL SOLUTIONS

-

STRETCHERS

-

COMPLEMENTARY FURNITURE

-

HEALTHCARE FACILITIES

MENU

CERTIFICATIONS

Healthcare, a sustainable future.

Deal with the present, thinking about the future.

This is the sustainability concept which is articulated in many ways in our mission. The Group got the UNI EN ISO 14001 certification attesting its commitment to environmental protection and the rational use of energy and natural resources.

Another fundamental aspect is a positive vision towards the social environment and territory so the company adopted a very precise Code of Ethics which is articulated in an Organisational model complying with Legislative Decree 231/2001 monitored by an internal control body.

In January 2020 the company has awarded the legality Rating by the Italian antitrust confirming the company operates according to the principles of fairness, transparency and sustainability.

The company was included among the 150 Italian companies Sustainability Leaders 2021, 2022 and 2023.

Quality healthcare.

Quality is our company attitude. It arises from the constant comparison between our R&D and the healthcare sector in order to better direct the design process to meet the needs and solve the problem in the patient care.

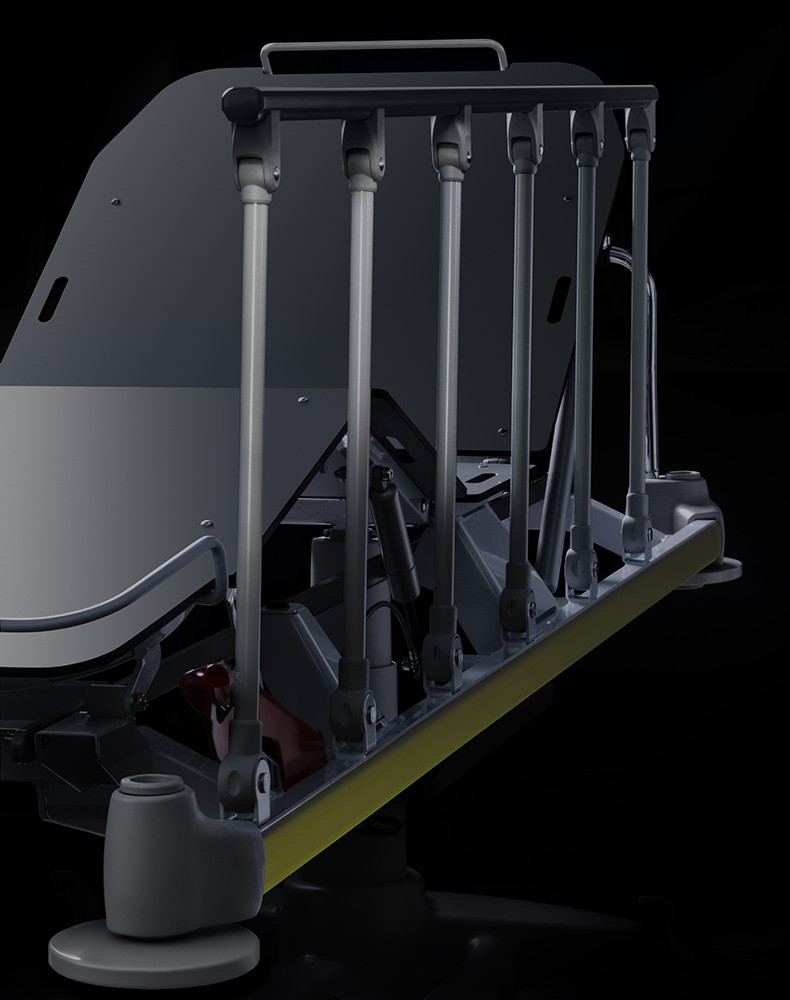

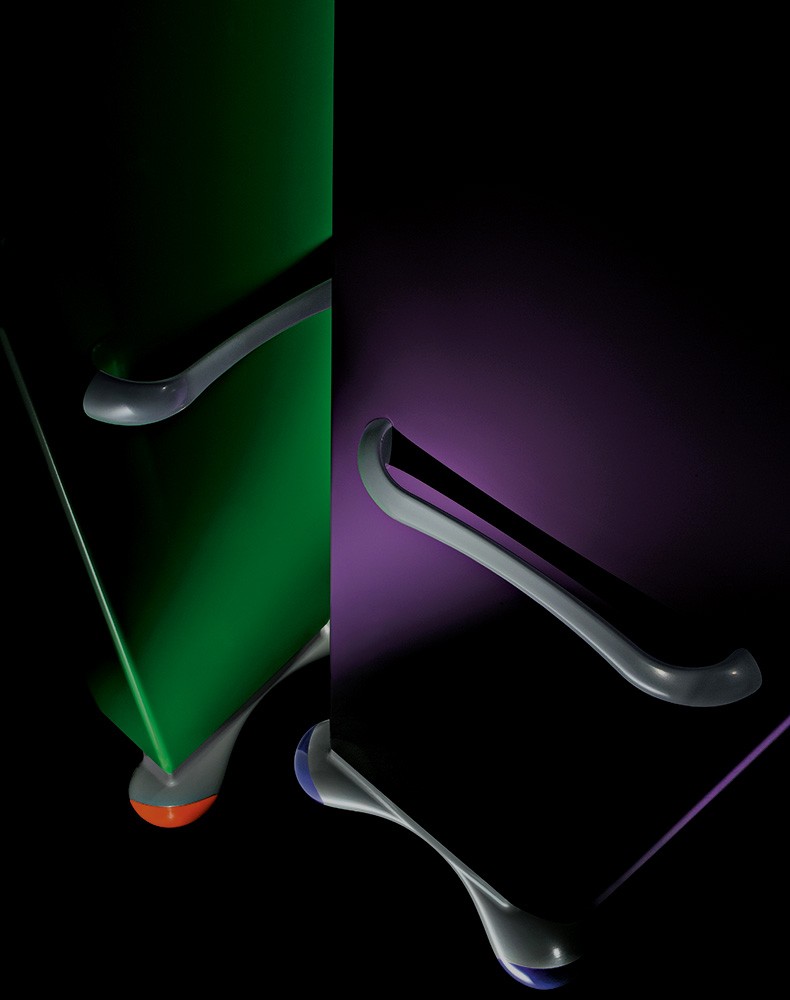

A lot of patents and innovations developed over the years from the bacterial protection system to the removable semi side rails. Technologically advanced production, strict tests of products, along with an attentive customer care service complete our quality attitude.

Favero Health Projects got the UNI EN ISO 9001 certification which guarantees the control of the productive process and its efficacy; and also UNI EN ISO 1345 which guarantees the safety of the medical devices placed on the market together with their traceability. All this in order to offer furnishing solutions which can be the reference point for quality, design, functionality, performance and efficiency.

Favero Health Projects S.p.A. works in full compliance with the following regulations:

| UNI EN ISO 9001as per Icila certificate No. SQ174215-ICILA, with its application scope being the “Design, manufacturing, trading, laying and assistance for supply of furniture and equipments for hospital, clinical and community.” It ensures control of the production process and its effectiveness. |

| UNI EN ISO 13485 as per Icila certificate CSQ No. 9124.FHPR, with its application scope being the “Design, manufacture, and placing on the market of medical devices such as electric beds, armchairs therapy, specialist visit beds, changing tables. Marketing of electric bed with weighing system." It guarantees the safety and traceability of medical devices placed on the market. |

| UNI EN ISO 14001 as per Icila certificate No. SGA16232-ICILA the scope of which is the “Design, manufacturing and trading for furniture and equipments for hospital, clinical and community through the process of cutting, folding and welding of iron, steel and aluminum elements, assembly, delivery, laying and assistance.” This regulation certifies and guarantees the company’s commitment to environmental protection and the rational use of energy and natural resources. Certified headquarters: Via Schiavonesca Priula, 18-20-23, 31044 Montebelluna (TV). |

Fill out our online form to send an email to our Customer Service team.

CONTACT US